Description

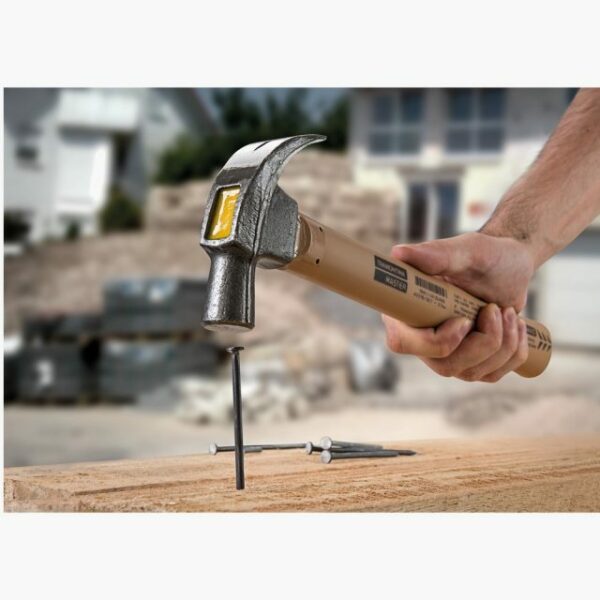

Forged special steel head.

Hardening on the striking face and ball.

Polished and varnished base and ball.

Fixed with steel wedge.

Varnished hardwood handle.

ASME B107.53.

The hammers are assembled in hydraulic press and the head is attached to the handle using a metal wedge. The strenght of this assembly is tested using a pull apart test.

The hammers are subjected to a specific hardening process to give a suitable hardness at the striking faces and peins to ensure a long life. Hardness tests are frequently carried out to guarantee the quality of the product.

In order to verify the material durability after the heat treatment, the hammers are also subjected to an impact test and analysed magnetically to detect any microscopic cracks, impact tests are also made so that magnetic particles can be analysed.

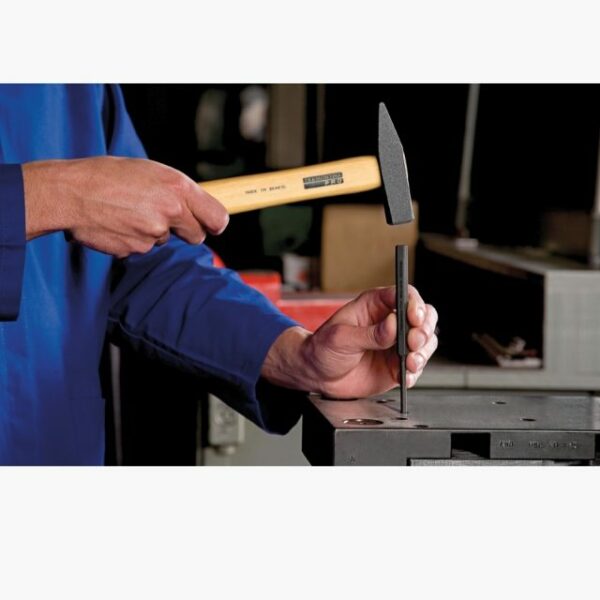

To strike chisels, wood chisels, and to rivet, form or straighten non-hardened steel.

Reviews

There are no reviews yet.